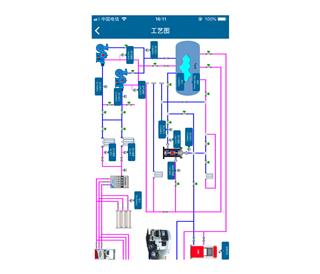

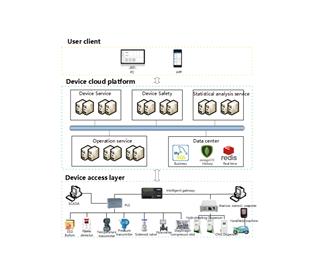

The clean energy equipment supervision system mainly implements real-time data collection and condition monitoring(mainly pressure, temperature, liquid level, differential pressure, gas concentration, valve position, flow rate and other physical data) on the entrance flowmeter, compressor, dehydration, desulfurization, gas storage well, alarm and various instruments & meters running in the LNG filling station, hydrogen refueling station and gasification station, in order to realize the remote detecting, sensing and signaling functions of equipment data in the station. The core idea of the clean energy equipment supervision system on the design: conducting the following acts for filling station and gasification station through a unified platform. Real- time monitoring and management of equipment.

System functions

1.Equipment recording and parameter management

2.Equipment monitoring and alarm

3.Device monitoring and station information

4.Equipment management and early warning

5.Editing and setup of equipment on monitoring

6.Real-time monitoring of equipment center and mobile terminals

7.Equipment inspection and task management

8.Troubleshooting management and maintenance

9.Status display of equipment process flow chart

System Features

1.Unified management of personnel

2.Unified supervision of equipment

3.Provide accurate and comprehensive operation and management data analysis for senior management

4.Provide the basis for business decision-making